ecolab advanced laundry control system manual

This manual provides essential guidance for the installation, operation, and servicing of the Ecolab Advanced Laundry Control System, optimizing laundry efficiency and reducing manual intervention through automation.

Overview of the System and Its Purpose

The Ecolab Advanced Laundry Control System is a cutting-edge solution designed to optimize laundry operations by automating key processes. Its primary purpose is to enhance efficiency, reduce manual intervention, and minimize human error. This system integrates seamlessly with existing laundry equipment, ensuring precise control over detergent dispensing, water usage, and cycle timing. By streamlining operations, it helps reduce operational costs and improve consistency in laundry quality. The system is particularly ideal for commercial and industrial settings where high-volume laundry processing is required. Its advanced automation features and comprehensive reporting capabilities make it a reliable choice for businesses seeking to modernize their laundry management. The Ecolab Advanced Laundry Control System is engineered to deliver superior performance while maintaining environmental sustainability, making it a versatile and effective solution for modern laundry needs.

Installation of the Ecolab Advanced Laundry Control System

The installation process involves connecting key components like the Machine Interface module and Controller, ensuring proper integration with existing laundry equipment. Follow the manual’s guidelines for a seamless setup.

Step-by-Step Installation Instructions

Begin by unpacking and inventorizing all components, including the Controller, Machine Interface module, and optional Flush Manifold. Connect the Controller to the Machine Interface, ensuring secure wiring. Next, link the system to your laundry equipment, following the manual’s detailed diagrams. Prime the system by opening the main water supply valve, as outlined. Finally, test the setup to ensure all functions operate smoothly. Refer to the manual for troubleshooting if issues arise during installation. Proper setup ensures efficient operation and minimizes downtime, adhering to Ecolab’s guidelines for optimal performance.

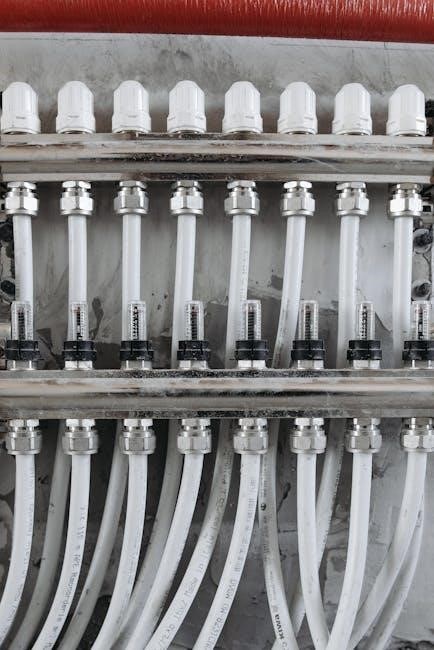

Key Components of the System

The Ecolab Advanced Laundry Control System comprises several essential components designed to streamline laundry operations. The Controller serves as the central hub, managing automation and chemistry delivery. The Machine Interface module connects to washing machines, converting signals to ensure seamless communication. An optional Flush Manifold enhances detergent distribution efficiency. Additionally, liquid dispensers are integrated to deliver precise chemical amounts, optimizing wash cycles. These components work together to ensure accurate dosing, reduce manual intervention, and improve overall laundry efficiency. Proper installation and maintenance of these parts are critical for system performance. The design ensures compatibility with various laundry equipment, making it a versatile solution for different facilities. By integrating these components, the system offers a comprehensive approach to laundry management, addressing key operational needs effectively.

Operation of the Ecolab Advanced Laundry Control System

The system automates laundry processes, delivering precise chemistry and optimizing wash cycles. Its user-friendly interface enables easy programming, ensuring efficient and reliable operation while minimizing manual oversight and errors.

Daily Use and Programming Guidelines

The Ecolab Advanced Laundry Control System is designed for seamless daily operation, offering automated solutions to streamline laundry processes. Users can program custom cycles and detergent dosing to meet specific needs. The system’s user-friendly interface simplifies programming, ensuring precise control over wash cycles, temperature, and chemical delivery. Daily use involves minimal manual intervention, as automation handles tasks like detergent injection and cycle monitoring. For optimal performance, follow the manufacturer’s guidelines for priming the system before initial use. Regularly review and adjust settings to maintain efficiency. The system also provides real-time feedback, enabling adjustments on the fly. Proper programming ensures consistent results, reducing errors and extending equipment lifespan. Always refer to the manual for detailed instructions on programming and troubleshooting common issues during daily operations.

Understanding the System’s Automation Features

The Ecolab Advanced Laundry Control System leverages cutting-edge automation to streamline laundry operations, minimizing manual intervention and enhancing efficiency. Key automation features include real-time monitoring of wash cycles, temperature control, and precise chemical dosing. The system automatically adjusts settings based on load size and fabric type, ensuring optimal cleaning while reducing waste. Automated alerts notify users of issues like low detergent levels or system malfunctions. The Machine Interface module and Controller work in tandem to process signals and execute tasks seamlessly. These features reduce human error and ensure consistent results. The automation also supports comprehensive reporting, providing insights into system performance and resource usage. By automating routine tasks, the system maximizes productivity and extends equipment lifespan, making it a reliable solution for modern laundry operations.

Maintenance and Servicing

Regular maintenance ensures the system’s longevity and efficiency. Check connections, clean components, and update software as needed. Refer to the manual for specific servicing instructions and troubleshooting guidance.

Regular Maintenance Tasks

Regular maintenance is crucial to ensure optimal performance of the Ecolab Advanced Laundry Control System. Daily checks include inspecting tubes and connections for leaks or blockages. Weekly, clean the dispenser nozzles and verify detergent levels. Monthly, review system logs for errors and perform software updates if available. Additionally, ensure all components are free from debris and functioning properly. Refer to the manual for detailed instructions on servicing and troubleshooting common issues. Proper maintenance prevents downtime and extends the system’s lifespan. Always follow the manufacturer’s guidelines for best results and consult Ecolab support if needed. Regular servicing ensures efficiency, accuracy, and reliability in laundry operations. By adhering to these tasks, users can maintain peak performance and minimize operational disruptions. This proactive approach safeguards the system’s functionality and ensures consistent results. Adhering to the maintenance schedule outlined in the manual is essential for long-term success.

Troubleshooting Common Issues

Troubleshooting the Ecolab Advanced Laundry Control System involves identifying and resolving common issues promptly to ensure uninterrupted operation. Start by checking error messages on the control panel, as they often indicate specific problems like low detergent levels or system malfunctions. If the system fails to dispense detergent, inspect the tubing for blockages or kinks and ensure the dispenser is properly primed. For connectivity issues, verify that all cables are securely connected and restart the system. If problems persist, refer to the manual for detailed troubleshooting steps or contact Ecolab support for assistance. Regular system checks and maintenance can help prevent many common issues. Always follow the manufacturer’s guidelines for resolving errors to avoid further complications. Timely troubleshooting ensures optimal performance and minimizes downtime in laundry operations. Consult the manual for a comprehensive list of potential issues and solutions.

Advanced Features and Benefits

The Ecolab Advanced Laundry Control System offers automation features that streamline laundry processes, reducing manual intervention and errors. Its smart dispensing technology ensures precise detergent delivery, while comprehensive reporting enhances efficiency and resource management.

Comprehensive Reporting and Efficiency

The Ecolab Advanced Laundry Control System features advanced reporting capabilities that provide detailed insights into laundry operations, including detergent usage, water consumption, and cycle tracking. This data helps identify inefficiencies and optimize resource allocation. The system’s automation ensures precise chemical dispensing, reducing waste and enhancing cleaning effectiveness. Real-time monitoring allows for prompt adjustments, improving overall efficiency. By streamlining processes and minimizing manual intervention, the system contributes to cost savings and improved operational consistency. These features make it an essential tool for facilities aiming to maximize productivity while maintaining high standards of cleanliness and sustainability. The comprehensive reporting functionality also supports long-term planning and maintenance scheduling, ensuring the system operates at peak performance. This integration of automation and analytics sets the Ecolab system apart as a modern solution for laundry management.

The Ecolab Advanced Laundry Control System Manual serves as a comprehensive guide for optimizing laundry operations through advanced automation and efficiency. By following the manual’s instructions, users can ensure proper installation, operation, and maintenance of the system. The integration of automation features and detailed reporting capabilities makes it an invaluable tool for streamlining laundry processes and reducing costs. Regular maintenance and adherence to troubleshooting guidelines help maintain peak performance and extend the system’s lifespan. With its user-friendly interface and robust functionality, the Ecolab system is designed to meet the demands of modern laundry facilities while promoting sustainability and operational consistency. By leveraging the manual’s insights, users can maximize the benefits of this cutting-edge technology and achieve superior results in their laundry operations.